End-to-end development and characterization of advanced aerosol formulations for precise and effective pulmonary drug delivery.

Scientific Leader / leaders of the project: Jesús Santamaría (U9) / José Luis Pedraz (U10)

Coordinator of the project: María Pilar Lobera & José Luis Hueso (U9) / Idoia Gallego & Ángela Losada (U10)

Respiratory infections caused by multidrug-resistant pathogens are particularly challenging to manage and are associated with substantial morbidity and mortality. In a scenario of escalating antimicrobial resistance, these infections represent an increasingly important global healthcare concern. Conventionally, they are treated via systemic administration but only a limited proportion of the administered antibiotic reaches pulmonary tissues, which can diminish efficacy and requires higher doses to achieve therapeutic effects.

Excess circulating drug may then distribute to non-target organs, increasing the risk of adverse effects, including gastrointestinal disturbances and ototoxicity. In contrast, inhalation offers important advantages related to the delivery of the drug directly to the lungs, i.e., the primary site of infection. This targeted deposition can achieve higher local concentrations and sustain antibacterial activity for longer periods while requiring lower total doses, thereby reducing systemic exposure, limiting side effects, and improving patients’ quality of life relative to other routes of administration. However, it is evident that new formulations are required to enable efficient, direct delivery to the lungs. Wet nebulization remains the most widely used approach for pulmonary administration of antibiotics; however, it has several limitations, including relatively complex administration procedures, a higher susceptibility to reinfection, reduced drug stability, and lower patient acceptance when compared with dry powder inhalers.

This Cutting-Edge Biomedical Solution (CEBS) represents a global solution for the development and full characterization of aerosolized formulations aimed at pulmonary administration, including the development of novel drug encapsulating biocompatible materials and even novel self-assembly of drugs for direct aerosolization. It also offers the possibility of exploring and adjusting the parameters required for the correct development of a successful formulation of the final product in an aerosolized form. A precise control on particle size and agglomeration is key to achieve delivery to the distal areas of the lung.

Examples of scientific publications and patents implementing this Cutting-Edge Biomedical Solution:

Examples of research projects implementing this Cutting-Edge Biomedical Solution:

Services involved:

These studies are carried out by the U9 (Synthesis of Nanoparticles Unit) at the Institute of Nanoscience and Materials of Aragon (CSIC-University of Zaragoza) and the U10 (Drug Formulation Unit) at the University of the Basque Country (UPV/EHU). These Units have previously been collaborating on projects of this type for the development and characterization of aerosol products. The steps and services involved in this cutting-edge solution are the following:

1. Consultancy. Analysis of the feasibility of the study of generation of aerosol formulations for pulmonary administration. The Unit can provide advice about the suitability of the aerosol generation conditions according to the nature of the targeted drug formulation requested by the user. U9-S06.

2. Generation of nanoparticle aerosols. This CEBS offers the possibility of generating nanoparticle aerosols from either a large variety of liquid suspensions or any preformed micro or nanoparticle powders. U9-S05.

3. Preliminary characterization of the aerosols. For determining the particle size and concentration in aerosol phase, several nanoparticle aerosol spectrometers are also available. These allow a real-time determination of the concentration of particulate matter and their size distribution in air streams and environments from sizes down to 5 nm. Also, the cutting-edge is able to identify nanosize matter from aerosols using a reliable, ultrasensitive identification in diverse matrices, based in introducing trace amounts of labels (eg. rare earth oxides or flurorophores). U9-S05.

4. In depth characterization of the pulmonary formulation. The developed formulations can be characterized, following SOPs, in terms of particle size, polydisperstity index and zeta potential, using the Zetasizer Nanoseries equipment. Additional parameters can be determined, such as, pH of the suspension. U10-S03.

5. Characterization of the droplet-size distribution of the pulmonary formulation. Real-time droplet size distribution by means of SprayTec technology for more efficient product development of sprays and aerosols, with robust and reproducible droplet size data. U10-S09.

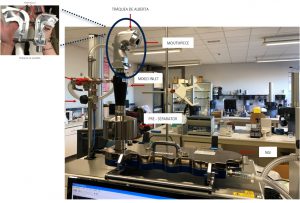

6. Analysis of the aerodynamic diameter of aerosol particles and their classification in the respiratory tract using Next Generation Impactor (NGI) technology can also be carried out, if desired. This equipment has been designed specifically for the pharmaceutical industry for testing metered-dose inhalers, dry powder inhalers, nebulizers and nasal sprays. This technology allows to determine how much active principle is retained in the different sections of what would constitute the respiratory tract: the idealized trachea of Alberta (or the pharmacopoeia induction port) and the different sections of the NGI stages, equivalent to the anatomy of the respiratory tract. Furthermore, it will be possible to simulate not only physiological respiration, but also respiration under pathological conditions, such as asthma, by means of a Breath Simulator. U10-S09.

|

Unit 9, integrated in the Nanostructured Films and Particles Group at the Institute of Nanoscience and Materials of Aragón (INMA) coordinated by Dr. Jesús Santamaría, has as objective the synthesis of nanoparticles with applications in biomedicine. The Unit provides an automated system for the synthesis of nanoparticles using laser-induced pyrolysis of chemical precursors in gas and/or aerosol phase, which enable either individual nanoparticles or biocompatible hybrid nanostructures to be produced in large quantities. In addition, this facility is able to draw on a wide range of nanoparticles fabrication technique, as well as having the necessary specialized personnel, to undertake exhaustive characterization of the microstructure, chemical composition, particles size and distribution of sizes, as well as magnetic, optical and colloidal properties and degree of biological functionality of the synthesized material. |

|

Located at the Faculty of Pharmacy, University of the Basque Country (UPV/EHU), Campus of Alava in Vitoria. The Unit 10 is led by Prof. José Luis Pedraz and consists of large laboratories for cell culture, chromatography equipment, sample preparation and characterization, and one specific for scale preparation of pharmaceutical formulations. Recently the group has incorporated 3D bioprinters of the last generation with different technologies based on extrusion, inkjet, among others. It has also incorporated self-assembly equipment of nanoparticles based on microfluidic technologies. This Unit can design and evaluate dosage forms both classical and new dosage forms of biotech drugs, DNA, RNA, and vaccines using different methodologies based on micro and nano-medicine and the latter technology based on the microencapsulation of cells, peptides, proteins, and in general of biotech products, as well as the development and design of non-viral vectors for gene therapy, is one of the biggest singularities of this Unit. It counts on the most advanced equipment for micro and nanoencapsulation. The Unit aims to determine experimentally all the variables needed to develop an optimal formulation and work instructions for preparing final pharmaceutical products. The pharmaceutical technology applied to drug development involves the selection of materials and procedures that can be adapted to different processes that lead to specific pharmaceutical forms. To do that, the Unit10 counts with the most advanced equipment to cover the development for all the steps of the process. One of the singularities of this Units is that is GLP certified by the Spanish Medicament Agency. |