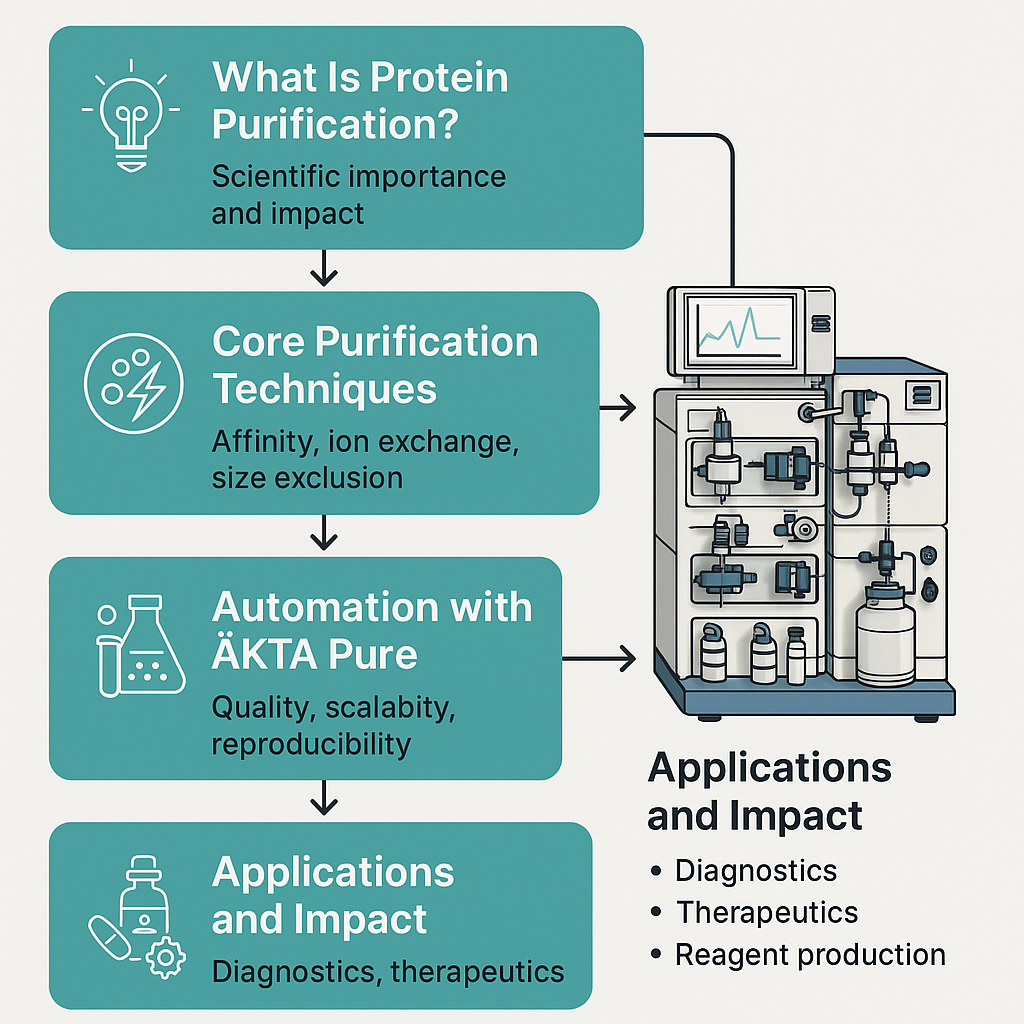

Explore modern protein purification methods with a special focus on automated systems like ÄKTA Pure. Learn how advanced chromatography workflows are transforming antibody production, diagnostics, and biotech applications.

What is protein purification and why does it matter?

Protein purification is a fundamental process in biotechnology, biomedical research, and pharmaceutical production. It involves isolating a specific protein of interest from a complex mixture, such as a cell lysate, while preserving its structure and function. This process is critical because the quality, purity, and yield of proteins directly impact downstream applications such as drug development, diagnostic assays, and therapeutic research.

In the context of immunoreagents, such as antibodies, protein purification ensures the removal of host cell proteins, nucleic acids, and other contaminants that may interfere with analytical or clinical performance. High-purity proteins are essential for reproducibility and reliability across scientific studies.

The traditional steps of protein purification

The protein purification workflow typically includes several key steps:

- Cell lysis and extraction: Disruption of the cell membrane to release intracellular contents using chemical, mechanical, or enzymatic methods.

- Clarification: Removal of insoluble debris through centrifugation or filtration.

- Buffer exchange and conditioning: Adjusting pH, salt concentration, and adding stabilizers to optimize protein behavior before chromatography.

Each step requires careful design to avoid loss of protein function or yield.

Overview of core purification techniques

Several chromatographic methods are widely employed:

- Affinity Chromatography: Exploits specific interactions between the protein and a ligand attached to a resin. Protein A or G resins are commonly used for antibody purification.

- Ion Exchange Chromatography (IEX): Separates proteins based on charge differences.

- Size Exclusion Chromatography (SEC): Also known as gel filtration, this method separates proteins based on size and shape.

- Precipitation and Filtration: Less specific methods used in early-stage purification, often resulting in variable quality.

The role of automation in protein purification: ÄKTA Pure

The ÄKTA Pure system represents a shift towards automation in protein purification. Developed by Cytiva, it integrates multiple chromatography techniques into a single, modular, and highly customizable platform.

ÄKTA Pure addresses key challenges in protein purification:

- Reproducibility: Reduces variability associated with manual processes.

- Contamination Control: Automation minimizes exposure and potential degradation.

- Optimization: Through UNICORN software, parameters like flow rate, pH, and gradient elution are finely controlled.

Its use of affinity, ion exchange, and size exclusion chromatography enables highly pure antibody isolation with reduced time and effort.

Comparative analysis: ÄKTA Pure vs other systems

While traditional systems like HPLC offer precision, they lack the flexibility and ease of method development found in ÄKTA Pure. Manual purification methods, although accessible, introduce variability and limit scalability.

Compared to other FPLC systems, ÄKTA Pure stands out due to:

- Integrated software (UNICORN) for intuitive protocol design

- Modular components for flexibility

- Scalability from research to pilot production

Applications and impact in the biomedical and biotech industries

The ÄKTA Pure system has a significant impact in fields requiring consistent, high-purity proteins:

- Diagnostics: Antibody production for ELISA and lateral flow assays

- Biotech R&D: Reliable protein reagents for drug screening and discovery

- Therapeutics: Preparation of immunoreagents for preclinical validation

Barriers to entry and practical considerations

Despite its advantages, implementing ÄKTA Pure may involve high initial equipment cost, training needs for advanced chromatography and software use, and infrastructure adjustments in existing labs.

However, these challenges are offset by long-term gains in quality, throughput, and compliance.

Near and long-term opportunities for automated protein purification

Short and mid-term applications include:

- Routine antibody purification for biomedical research

- Development of high-performance diagnostic reagents

- Protocol refinement to increase yields and consistency

Looking forward:

- Integration with AI for adaptive protocol optimization

- Large-scale purification of advanced antibody formats (e.g., bispecifics, ADCs)

- Continuous processing for industrial-scale immunoreagent production

NANBIOSIS case study: Integrating ÄKTA Pure into CABS services

The CABS platform within NANBIOSIS incorporates ÄKTA Pure to support:

- Rapid adaptation to different antibody types

- Regulatory-compliant workflows

- Expert-guided optimization for diverse client needs

This integration allows seamless transition from research protocols to industrial applications, drastically decreasing the challenges of the technique, and enhancing efficiency and reliability.

Conclusion

Modern protein purification is evolving from manual methods to intelligent, automated systems. ÄKTA Pure exemplifies this shift, offering robust solutions to common challenges in protein production. As the demand for high-quality immunoreagents grows, adopting flexible, scalable purification systems will be key to innovation in diagnostics, therapeutics, and beyond.

Credits:

Nuria Pascual

Gabriel Alfranca

What is NANBIOSIS?

The goal of NANBIOSIS is to provide comprehensive and integrated advanced solutions for companies and research institutions in biomedical applications. All of this is done through a single-entry point, involving the design and production of biomaterials, nanomaterials, and their nanoconjugates. This includes their characterization from physical-chemical, functional, toxicological, and biological perspectives (preclinical validation).

Leading scientists

The main value of NANBIOSIS is our highly qualified and experienced academic scientists, working in public institutions, renowned universities and other research institutes.

Custom solutions

Designed for either scientific collaboration or the private industry, we adapt our services to your needs, filling the gaps and paving the way towards the next breakthrough.

Cutting-Edge facilities

Publicly funded, with the most advanced equipment, offering a wide variety of services from synthesis of nanoparticles and medical devices, including up to preclinical trials.

Standards of quality

Our services have standards of quality required in the pharmaceutical, biotech and medtech sectors, from Good Practices to ISO certifications.

In order to access our Cutting-Edge Biomedical Solutions with priority access, enter our Competitive Call here.

NANBIOSIS has worked with pharmaceutical companies of all sizes in the areas of drug delivery, biomaterials and regenerative medicine. Here are a few of them: