New equipment adquired to improve NANBIOSIS U20

NANBIOSIS, U20. In Vivo Experimental Platform, led by Dr. Ibane Ibasolo, has been updated and improved as a result of its participation in the project FICTS1420-20, selected by the MICINN for co-financing by the FEDER Program in ICTS 2014-2020 (Equipment for setting standardized immunotoxicology assays for the U20 -NANBIOSIS I17 Action of the Investment Plan-)

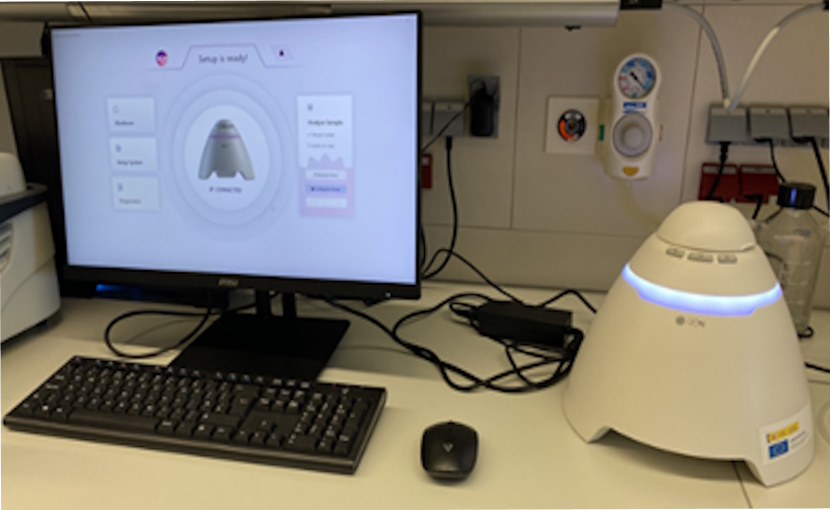

A particle particle analyzer equipment (Exoid) has been inslalled at NANBIOSIS U20 for measurement of the concentration and the size of nanoparticles. The Exoid is the latest instrument from the Izon company to measure the physical characteristics of nanoparticles in electrolytic solution. Based on Tunable Resistive Pulse Sensing (TRPS) principles, the equipment is capable of measuring the size of the particles, their concentration and Z potential, through the use of a nanopore that allows measurements to be made in a defined size range.

Finally, a new upright laboratory freezer Liebherr _ SFNe 5227 has been adquired for the storage of the samples and reagents used in the different services of FVPR/U20,